Design for Salicru company (Barcelona) of a electronic dimer for domestic use.

Despite our best efforts, the project was not successfully industrialized. However, this setback allowed us to identify areas for improvement and refine our approach for future projects.

As part of my main tasks on the project, I was responsible for design, modeling, development, animation, studying industrialization, and cost control. While we were unable to fully industrialize the project, our efforts in these areas yielded valuable insights that will inform our work moving forward.

By closely analyzing the project's shortcomings and areas for improvement, we have identified several key strategies for future success. These include a more rigorous study of industrialization, greater attention to cost control, and more thorough testing and prototyping to ensure a successful outcome.

While the project may not have reached the desired outcome, the experience gained from this endeavor will be invaluable in driving future success.

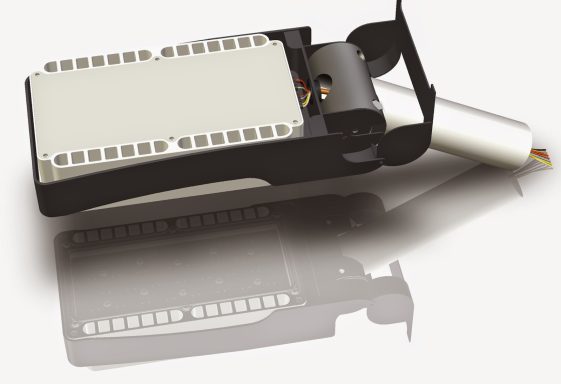

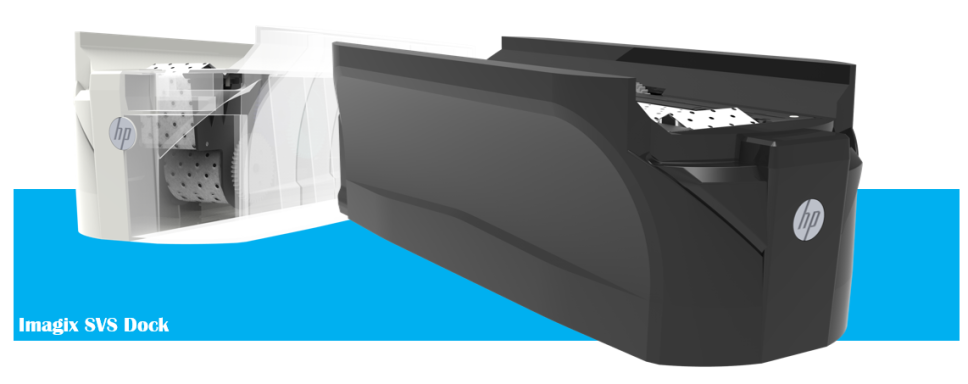

Design of mechatronic parts of the HP latex printer

From 2015 to 2016, I was fully involved in a project with the HP team, where we successfully launched a new product that allows printing on rigid media. As a key member of the team, I was responsible for designing and developing the mechatronic subsystems of the printer. Simultaneously, I oversaw the production line in Singapore, ensuring it was ready for mass production. Through my dedication and hard work, we were able to deliver a cutting-edge product that provides users with the ability to print on a wide range of materials. My contributions to this project demonstrate my ability to manage multiple tasks efficiently while maintaining a focus on delivering high-quality results.

Design of a Led street lamp for Salicru company

This project involved designing a modular LED luminaire for street lighting that unfortunately was never commercialized. Despite this, we are proud of the key features we developed:

We were able to assemble the LEDs PCB and driver with a single aluminum die-cast, reducing production costs and simplifying the assembly process. The luminaire also had impressive protection levels, with an IK10 rating for impact resistance and an IP0 rating for water resistance. Additionally, the piece used to join the luminaire to the mast allowed for easy orientation adjustments.

We also prioritized ease of maintenance and replacement with this design. The luminaire's modules were easily replaceable, and the driver was accessible for maintenance purposes. Throughout the project, we made multiple prototypes and designs until we were able to optimize the product.

Although the final luminaire housing was designed in plastic, it was never tested. However, we remain confident in the product we developed and believe that it would have been a reliable and efficient addition to street lighting.

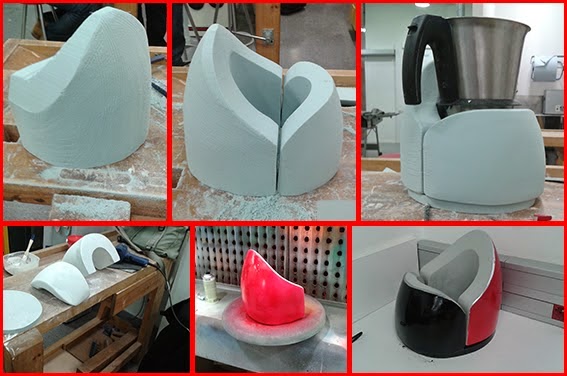

Design for Taurus company of a induction blender.

I had the privilege to collaborate with Karen Lua and Lluís Ramírez on a design project for Taurus company, where we developed an induction blender. Our focus was on re-styling the existing product, named Mycook, while improving its key features. Our team was responsible for the concept, sketch, mock-up, and render of the product.

To begin the project, we conducted a customer analysis and trend study to identify the product's weaknesses and determine potential new customers. This research provided us with strong insights that guided our design process.

Our key objectives were to reduce the product's footprint by 30%, reduce vibrations and noise, and design modular baskets for steam cooking that could be nested inside each other for easy storage. We also wanted to create a new user interface based on user experience.

Through our design process, we went through two phases: sketching and mock-up work. The final result was a sleek and functional product that addressed the previous product's weaknesses while improving its overall user experience. We are proud of the work we accomplished for Taurus, and we look forward to future projects where we can apply our expertise to design innovative solutions.

Design for Salicru company (Barcelona) of several UPS families.

Main functions : Design, mechanical development, deal with costumers, cost control, packaging, start up production in China.

Main objectives achieved: In the cube3 + project I managed to reduce the price of the entire range on average 30%, strengthening the quality of these, I improved manufacturing processes. I managed to increase the capacity of maritime shipping containers through the packaging design on a damping system and stacking.

This product was marketed by at least 11 companies, which reflects that the final product was attractive and competitive. The company increased the sales considerably thanks to an attractive design and competitive price to get one of the most compact products on the market.

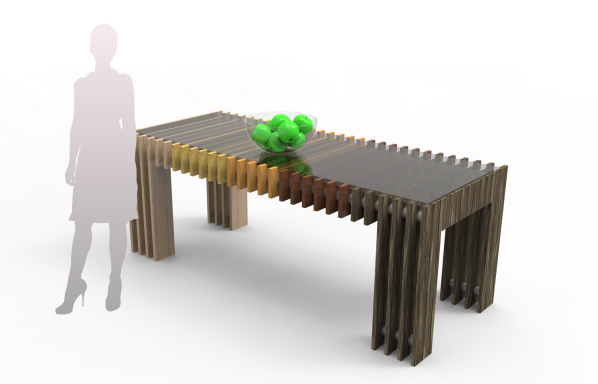

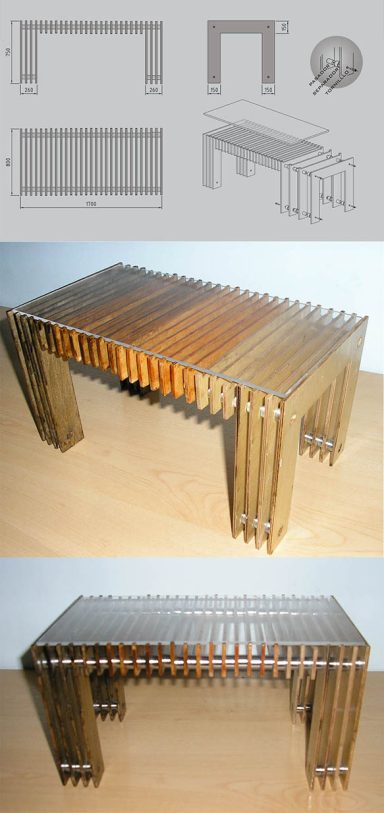

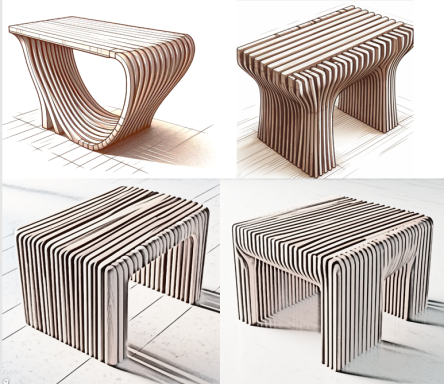

Design of a Table for AHEC

American Hardwood Export Council

I wanted to share a unique project that I worked on for the American Hardwood Export Council (AHEC). As part of their promotion efforts, we designed and built a table to showcase different types of wood. This table features multiple sheets, each made of a different type of wood, allowing us to create a comprehensive sample book of all the woods promoted by AHEC. The end result was a visually stunning and educational display of the diversity and beauty of American hardwoods. Through this project, we were able to highlight the unique characteristics and potential applications of each wood type, promoting the use and export of American hardwoods. It was a privilege to work on such an innovative and meaningful project, and I hope to have the opportunity to work on similar initiatives in the future.

Sketching Process

When I get the lowdown on a project, my first move is to really dive into all the info, picking out the main themes, what's needed, and any limitations. Once I've got the gist of the project, it's onto the fun part: coming up with ideas. This is where I let my imagination run wild and start turning abstract thoughts into something concrete. Sketching is a big part of this, it helps me visualize different possibilities and directions

When it's time to put ideas down on paper, I start with a blank page and a bunch of thoughts bouncing around in my head. I grab a pencil (or sometimes a pen if I'm feeling bold) and just start doodling.

These aren't masterpieces by any means :) they're more like rough sketches or scribbles. I jot down whatever comes to mind, whether it's a shape, a layout, or just a random line that sparks something. It's all about getting those ideas out of my head and onto the page.

As I keep sketching, things start to take shape. I'll refine certain parts, erase others, and maybe add a splash of color here and there. It's a bit like sculpting with lines and shapes, molding them until they start to resemble something coherent.

Sometimes, I'll sketch out a few different variations of the same idea, just to see which one works best. Other times, I'll stumble onto something completely unexpected that ends up being even better than what I originally had in mind.

The key is to stay open-minded and let the creativity flow. Sketching isn't about getting everything perfect on the first try – it's about exploring possibilities and seeing where they lead. And who knows? Sometimes the most brilliant ideas come from the messiest sketches.

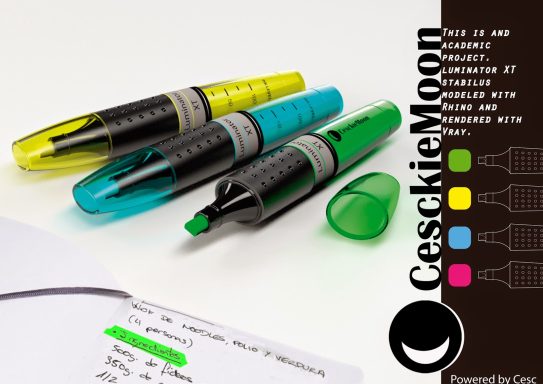

Marker Satabilus XT modeled with Rhino and redended with Vray

This project showcases my skills in 3D modeling and rendering, utilizing Rhino for modeling and V-Ray for rendering, resulting in a photorealistic representation of the product.

Design Process

1. Conceptualization

I began by gathering reference materials and sketching initial concepts to establish the visual and functional aspects of the Marker Stabilus XT. The focus was on creating a sleek design that reflects the marker's innovative features.

2. Modeling in Rhino

Using Rhino’s NURBS modeling capabilities, I developed the marker through a structured process:

- Base Shape Creation: I established the overall form with simple geometric shapes to define the proportions.

- Refinement: Leveraging control points, I meticulously refined the body’s curvature to enhance ergonomics, ensuring a comfortable grip.

- Detailing: I modeled components such as the nib and cap separately, using Boolean operations for precise intersections and maintaining clarity.

- Material Application: Initial materials and textures were applied within Rhino to simulate the marker's real-world appearance.

3. Rendering with V-Ray

With the model complete, I turned to V-Ray to create stunning visual representations:

- Scene Setup: I arranged lighting to replicate natural conditions, employing area lights and HDRI for realistic reflections.

- Material Shaders: I crafted a custom shader for the marker’s body, incorporating textures to evoke the feel of plastic and metal.

- Camera and Composition: Fine-tuning camera settings, including depth of field and exposure, allowed for a compelling visual narrative.

- Post-Processing: Final adjustments were made in Adobe Photoshop, enhancing color, contrast, and highlights to achieve a polished look.

Conclusion

The Marker Stabilus XT project exemplifies my ability to merge design aesthetics with functionality, utilizing advanced tools to create visually striking and practical products. This work not only highlights my technical skills but also my commitment to delivering high-quality design solutions.

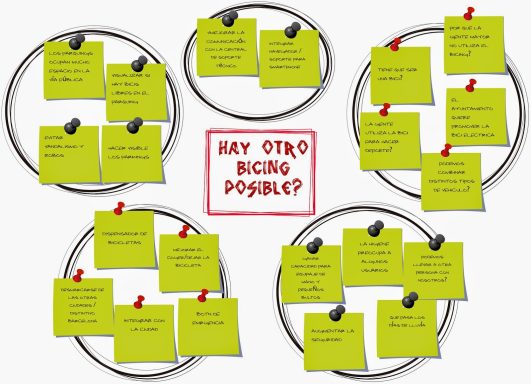

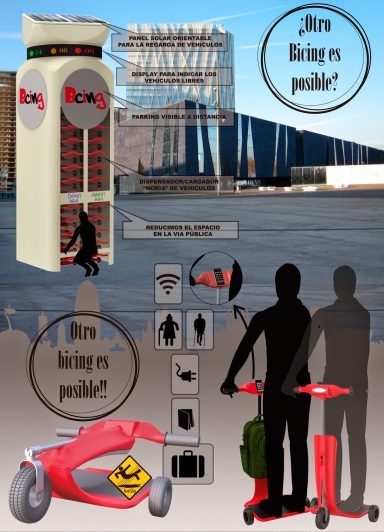

Design proposal to improve the Bicing services in Barcelona.

This project was ahead of its time, as it was conceptualized and developed before the current boom of scooters.

This project was exhibited at the H2O Gallery in Barcelona .

This proposal is aimed at providing solutions to some of the existing problems with the current cycling service in Barcelona. Many people either do not know how to cycle or may have physical limitations, which is why we suggest replacing traditional bikes with electric scooters. The scooters we propose are collapsible for easy storage and offer a convenient solution for those who need to travel short distances quickly.

Another area we focused on improving was the need for users to carry small items such as hand luggage or connect their smartphones or tablets for navigation purposes. Our design addresses this need by including a storage area for personal items and a smartphone holder on the handlebars.

Current Bicing stations occupy a lot of space on the street, which is why we have designed a dispenser vehicle with a vertical construction that reduces the amount of space needed. This dispenser can be remotely monitored to show how many vehicles are available or are currently being recharged.

The scooter dispenser has two doors, one for leaving the vehicle and the other for collection. It is designed to charge the scooters' batteries using a swiveling solar panel. This dispenser works like a vending machine and offers a convenient and eco-friendly way to provide electric scooters to users

Overall, our proposal provides a practical and innovative solution to the existing problems with the current cycling service. The inclusion of electric scooters, smartphone holders, and storage space for personal items, combined with a space-saving dispenser design, offers a convenient and eco-friendly way for users to travel short distances quickly and efficiently.

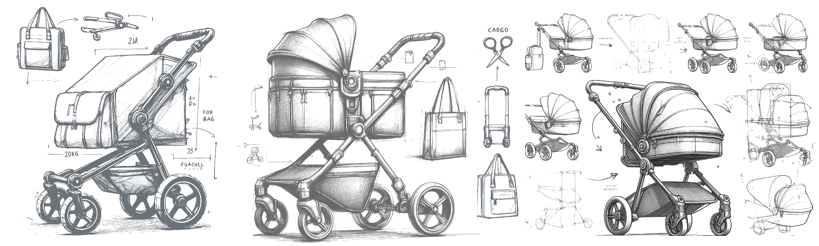

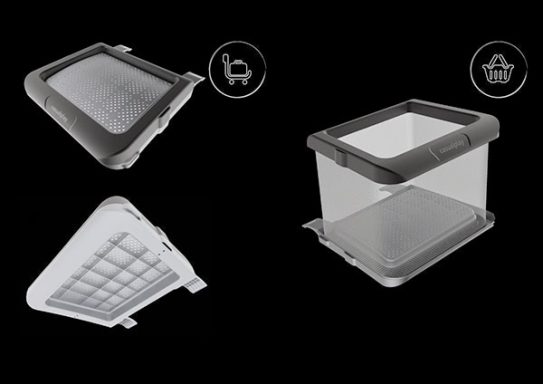

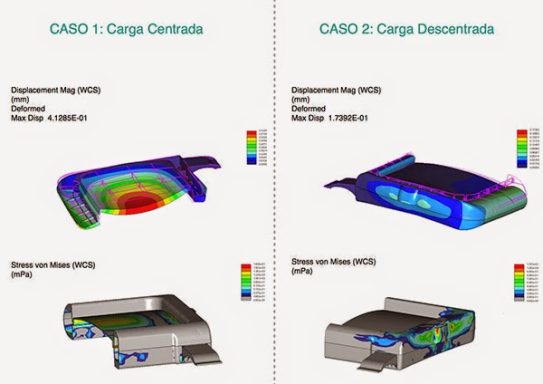

Design for Casualplay company (Barcelona) of a cargo system for a baby carriage

Collaborating with Laia Baró and Salvatore Coppola, I was involved in the design of an innovative solution to a common problem faced by families with young children when traveling, shopping, or going to the park

Our main tasks in this project included concept development, modeling, material selection, CAE, and prototyping. The result of our efforts was a platform that attaches to the back of a stroller, eliminating the need to handle a multitude of accessories while also carrying luggage or shopping bags.

Thanks to the excellent balance loads, the platform doesn't require an additional wheel. Additionally, the platform can be opened and transformed into a bag to carry purchases or other accessories

Our specially designed cargo system can carry up to 20kg of hand luggage, making it easier for families to move around airports, malls, parks, and other locations. By addressing a common pain point for parents, we believe our platform can make a significant difference in the lives of families with young children.

I'm proud of the innovative solution we developed and I look forward to continuing to create practical and effective designs that improve people's lives.

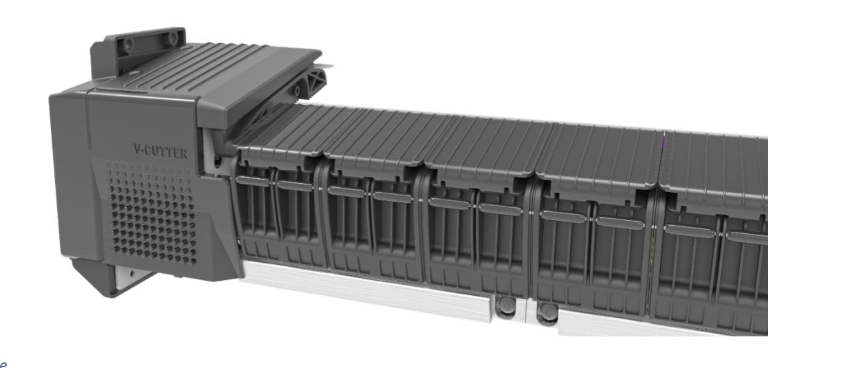

DESIGN OF A VERTICAL CUTTER FOR PRINTERS

Our team has successfully designed and developed several proposals for automatic vertical cutters that can be integrated into HP printers. These cutters are designed to be automatically positioned and can be enabled or disabled depending on the user's needs. We are proud to say that some of our innovative design solutions have been patented. Our focus on creating user-friendly and efficient solutions has resulted in products that enhance the printing experience for users. Our automatic vertical cutters provide precision cutting for a variety of media types, making printing tasks quicker and easier.

DESIGN OF A MULTI MONITOR MULTIMEDIA SYSTEM FOR CONFERENCE MEETING ROOM

In collaboration with the Electrical and SW engineer I designed and developed a mechanism for a multi-monitor system, which has been patented as a utility model. This innovative unit allows for seamless integration of multiple monitors, improving the user's overall experience and productivity. Our focus on design and development resulted in a product that stands out in the market, and we are proud to have our innovation recognized with a utility model patent.

HANDHELD PRINTER

Our team has designed and developed a handheld printer module along with its service module. This cutting-edge technology allows users to easily print from anywhere, enhancing their mobility and productivity. Our focus on design and development has resulted in a compact, lightweight, and user-friendly device that stands out in the market. The service module ensures that the printer is always functioning at optimal levels, providing users with consistent and reliable performance.

Design and development of a scoreboard for sports hall

In 2016, upon completing my Master's degree, I moved to Vienna where I teamed up with two talented individuals, Jose Perez and Daniel Revilla, to create a startup.

Our aim was to develop and build scoreboards for sports halls, as we identified a gap in the market for such a product. We believed that this product could be the foundation for sustaining our future projects, which would require significant investment.

After designing and developing our first prototypes, we were pleased to discover that our product exceeded the competition in terms of both features and functionality. Our scoreboard was easy to install and repair, and we created a console that connected with the scoreboard via RFID, giving users full control over the product.

We took pride in the fact that we developed both the software and hardware ourselves, ensuring that we had full control over the quality and features of the product. Overall, our scoreboard offered an exceptional user experience, and we were excited to bring it to market.

While it was disappointing not to be able to take the final step in creating our start-up, it was also a valuable learning experience. We discovered that starting a business requires a significant amount of financial resources, and without adequate funding, it can be challenging to succeed.

Despite our setback, we did not give up on our vision. Instead, we continued to explore opportunities for future projects and remained committed to finding ways to turn our ideas into reality.

We also recognized the importance of having a clear understanding of our prospects for success. It is essential to thoroughly research the market and industry before launching a business to ensure that there is a viable customer base and a realistic path to profitability.

Although we were not able to create the start-up at that time, we gained valuable insights that would prove beneficial in our future endeavors. We learned the importance of careful planning, financial management, and perseverance. These lessons helped us navigate challenges and stay focused on our goals as we pursued other opportunities in the years to come.

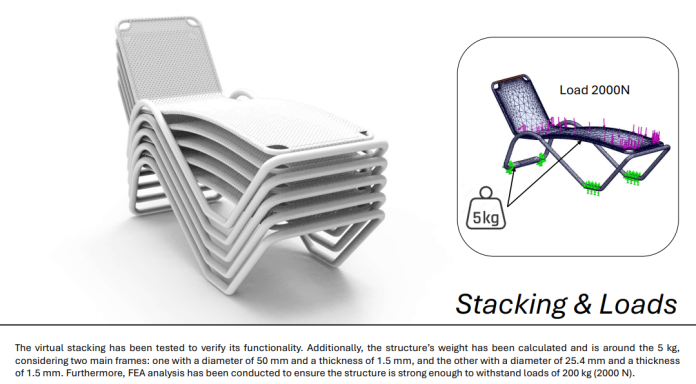

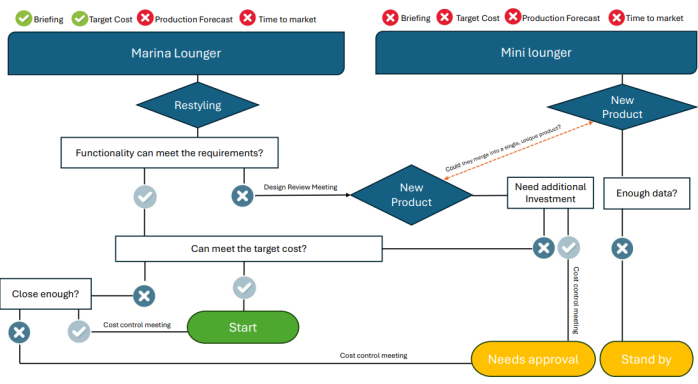

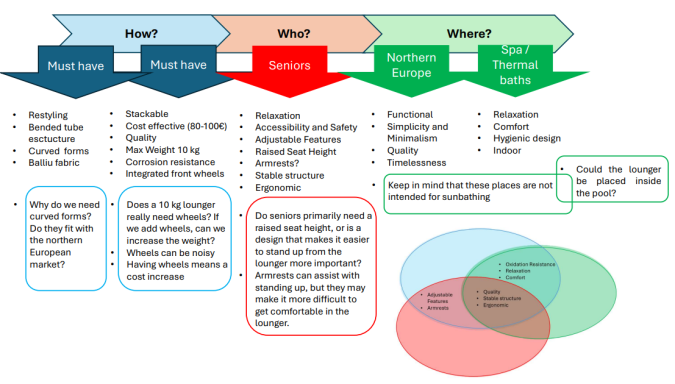

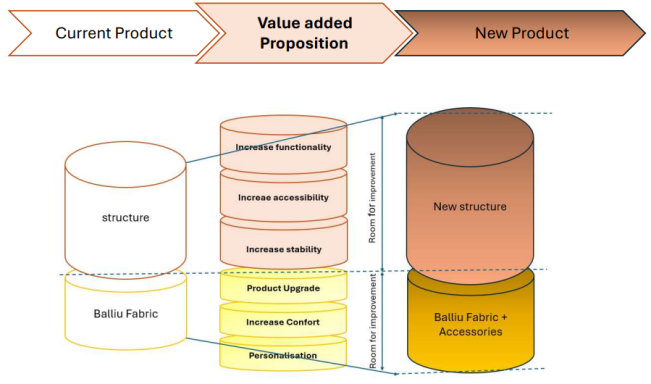

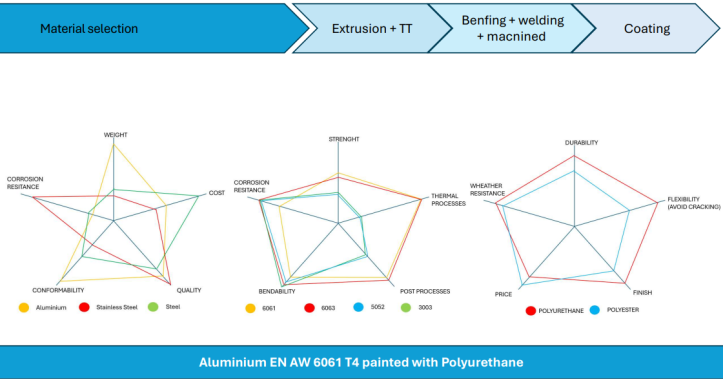

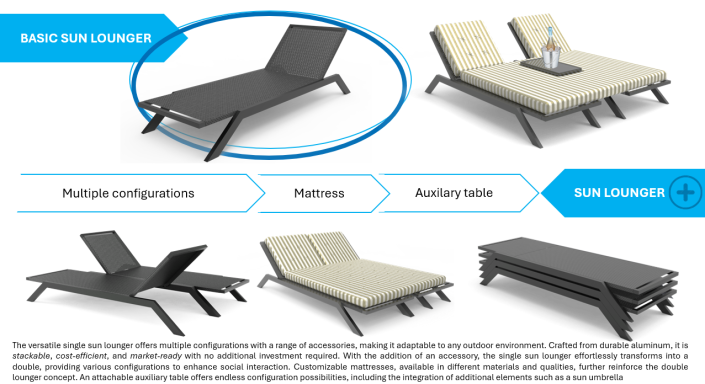

Exploring the loungers Field

Design exercises offer a valuable opportunity to dive deeper into the everyday products. In this case, I was tasked with designing a lounger specifically for the Northern European market, where loungers are commonly used in thermal baths and spas. This project presented unique challenges, and here's how I approached it.

Besides focusing on the final outcome, exploring various approaches during the design process is crucial for innovation and problem-solving. Each product has unique requirements, especially when considering cultural preferences, functionality, and user experience. For instance, designing a lounger for Northern European markets meant thinking beyond aesthetics and comfort. I had to consider how these loungers would be used in spa or thermal bath environments, where durability, materials suited for humid conditions, and ergonomic support play a significant role.

Exploring different design approaches allowed me to experiment with materials, shapes, and even the positioning of the lounger to enhance the relaxation experience. Sketching initial concepts, were key steps in refining the design. Each iteration brought new insights and helped me fine-tune details such as adjustability, portability, and ease of maintenance.

By exploring various approaches, I could ensure that the final design not only met practical needs but also aligned with the specific lifestyle and expectations of the target market. This exploratory phase is vital in any design process because it opens the door to creative solutions that might not have been obvious at first glance. In the end, the journey is just as important as the destination when it comes to delivering a product that truly resonates with its users."

Design & Development of a sublimation device

In this project, I developed a system for industrial sublimation purposes, from the initial concept to the first prototypes. While the product development was certainly exciting, the most fascinating aspect of the project was creating an electrostatic precipitator to remove the vapor. This technology proved to be essential in ensuring the efficient and safe operation of the system. With the electrostatic precipitator in place, we were able to effectively remove the vapor and prevent any potential hazards. Overall, this project was a great success, and I am proud to have contributed to the development of a cutting-edge system for industrial use.

One of the primary challenges of this project was effectively managing the thermal aspects of the system, as well as ensuring proper insulation to guarantee safety and prevent material deterioration. These were crucial considerations, as the system needed to operate at high temperatures without compromising safety or damaging the materials involved. We addressed these challenges by carefully selecting high-quality insulation materials and implementing advanced thermal management techniques, which allowed us to achieve optimal performance while ensuring the safety and longevity of the system. Despite the complexities involved, we were able to overcome these challenges and develop a highly effective system that met all our requirements.

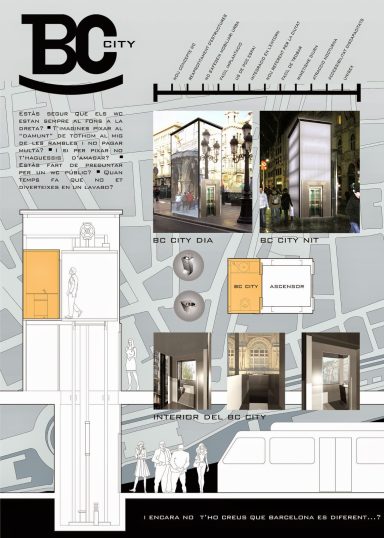

Design proposal for public baths in the city of Barcelona.

Collaborating with Mireia Brandariz and Kristina Pavlovaite, we undertook a project aimed at addressing the pressing issue of public toilets in cities. Not only are their locations often unsuitable, but users also face challenges in locating them, while cleanliness and safety concerns persist.

Our solution was to place the toilets in the elevators of subway stations, thus utilizing an existing structure while also improving visibility and safety. The unique experience we aimed to create involved placing the public bathroom on a higher floor, thereby affording users a breathtaking view of the city. We ensured privacy by using windows that allowed views from the inside out, but not vice versa.

Our innovative approach was recognized when our project was selected as a finalist in the prestigious ADI-FAD contest, and our work was exhibited at the FAD Gallery in Barcelona. By creating a practical and engaging solution to a widespread problem, we hope to inspire further innovation in this important area.

©copyright All rights reserved.

Necesitamos su consentimiento para cargar las traducciones

Utilizamos un servicio de terceros para traducir el contenido del sitio web que puede recopilar datos sobre su actividad. Por favor revise los detalles en la política de privacidad y acepte el servicio para ver las traducciones.